What is Brake Disc Skimming?

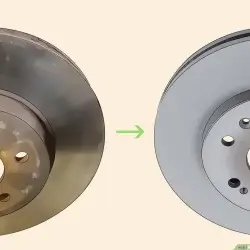

Brake disc skimming is precision machining that removes surface imperfections from your rotors. This process eliminates grooves, warping, and uneven wear—restoring smooth braking performance without the cost of full disc replacement.

Your brakes feel shaky when you stop. You notice pulsing through the pedal or steering wheel vibrations at highway speeds. These signs often point to warped or uneven brake rotors—and brake disc skimming can fix this without the cost of full replacement.

So what exactly is brake disc resurfacing? This process uses precision machining equipment to remove a thin layer of metal from your rotor surface. Brake rotor skimming eliminates grooves, scoring, and minor warping that develop from Dubai's extreme heat and constant stop-and-go traffic. The result is a perfectly flat, smooth surface that grips your brake pads evenly again.

Why should you consider disc brake skimming over buying new rotors? The answer comes down to cost and sustainability. Brake disc machining costs significantly less than replacement parts. You restore proper braking performance, eliminate those annoying vibrations, and extend your rotor life—all while reducing unnecessary waste.

When does brake rotor resurfacing make sense for your vehicle? This service works best when you experience pedal pulsation, notice minor surface damage, or plan to install new brake pads. However, your discs must have sufficient thickness remaining. A technician should always measure disc thickness first to confirm whether brake disc skimming service is the right solution for your situation.

Brake Disc Skimming Service: The Complete Guide

Your brakes feel shaky when you stop. You notice pulsing through the pedal or steering wheel vibrations at highway speeds. These signs often point to warped or uneven brake rotors—and brake disc skimming can fix this without the cost of full replacement.

What Causes Brake Vibration While Braking?

Brake vibration while braking happens when your rotor surface becomes uneven. Heat cycles from Dubai's intense temperatures cause metal expansion and contraction. Over time, this creates high and low spots that your brake pads hit unevenly, producing that pulsing sensation through your pedal.

Why Does Your Steering Wheel Shake When Braking?

Steering wheel shake when braking signals front rotor problems. Your front brakes connect directly to steering components, so any rotor irregularity transfers vibration straight to your hands. Brake disc resurfacing restores the flat surface needed for smooth, controlled stops.

How to Fix Uneven Brake Disc Wear

Uneven brake disc wear develops from stuck caliper pins, worn pads, or poor-quality rotors. Brake rotor skimming machines the surface back to uniform thickness. This disc brake skimming process removes damaged material and creates fresh contact area for your pads.

The Solution for Warped Brake Discs

Warped brake discs result from excessive heat buildup during hard braking. Brake disc machining corrects minor warping by cutting away distorted metal. This brake rotor resurfacing approach saves money compared to complete rotor replacement.

Effective Brake Judder Fix

Brake judder fix starts with professional diagnosis. Our technicians identify whether judder comes from disc runout, thickness variation, or pad deposits. Proper brake disc skimming service addresses these issues and restores confident braking performance.

Noisy Brakes Solution That Works

Noisy brakes solution often involves resurfacing rather than replacement. Grooved or scored rotors create grinding and squealing sounds. Brake disc machining removes surface imperfections and eliminates metal-on-metal contact points causing unwanted noise.

When Should Brake Disc Skimming Be Considered?

Skimming is usually necessary when the brake discs show signs of wear or damage but are still within their recommended thickness range. Indicators for skimming include vibration or pulsation when applying the brakes, a noticeable decrease in braking efficiency, or visible grooves and uneven surfaces on the disc.

However, if the disc has worn beyond its minimum thickness limit or shows signs of severe damage, replacement is the only option. Regular maintenance and inspection of the braking system can help identify the right time for skimming.

Environmental Impact

Brake disc skimming is an environmentally friendly practice. By resurfacing existing discs, it reduces the need for new manufacturing and minimizes waste. This process aligns with sustainable automotive maintenance practices, promoting eco-conscious choices for vehicle owners.

Common Misconceptions

Some vehicle owners may hesitate to opt for brake disc skimming, fearing it might compromise safety or performance. However, when performed correctly by skilled professionals, skimming ensures the disc's integrity and functionality are fully maintained. It is essential to consult a trusted service provider to achieve optimal results.

Final Thoughts

Brake disc skimming is a practical, economical, and sustainable solution for maintaining braking efficiency. By resurfacing the discs, it restores their smoothness and prolongs their lifespan, ensuring safe and comfortable driving. Regular brake system maintenance, including skimming when necessary, contributes to a safer driving experience and cost savings in the long run.

Frequently Asked Questions

Is Brake Disc Skimming Better Than Replacing the Discs?

At iTyreCare, we always check whether your discs can be saved before recommending replacement. Brake rotor resurfacing removes a thin layer from the disc surface to eliminate grooves, scoring, and uneven wear. If enough material remains, you get smooth braking again at a fraction of new disc costs.

Can All Brake Discs Be Skimmed?

At iTyreCare, we check every disc before deciding whether skimming works for your situation. If you experience brake pulsing or vibration through the pedal, skimming might fix it—but only if your discs have enough thickness left to machine safely. Not every disc qualifies, and skimming one that's too thin creates bigger problems.

Is Brake Disc Skimming Safe?

Yes—when done properly, disc brake skimming is completely safe for restoring your brake discs. At iTyreCare, we use precision equipment and measure every disc before skimming to ensure sufficient material exists. The process removes a thin, even layer from the surface, leaving you with a disc that performs like new.

How Long Does Brake Disc Skimming Take?

At iTyreCare, brake disc machining usually takes between one to two hours from start to finish. You don't need to leave your car all day—most customers wait at the workshop or step out and return when it's done. We provide an accurate time estimate once we examine your discs.

Service Description

At iTyreCare, we provide professional brake disc skimming service in Dubai to restore the performance and safety of your braking system. Using advanced tools and techniques, we ensure your brake discs are resurfaced with precision, eliminating imperfections like grooves or rust. Our experts prioritize quality and safety, extending the life of your brake system while saving you money. Visit our garage today for reliable, eco-friendly, and cost-effective car brake repair service tailored to your needs. Drive safe with iTyreCare!